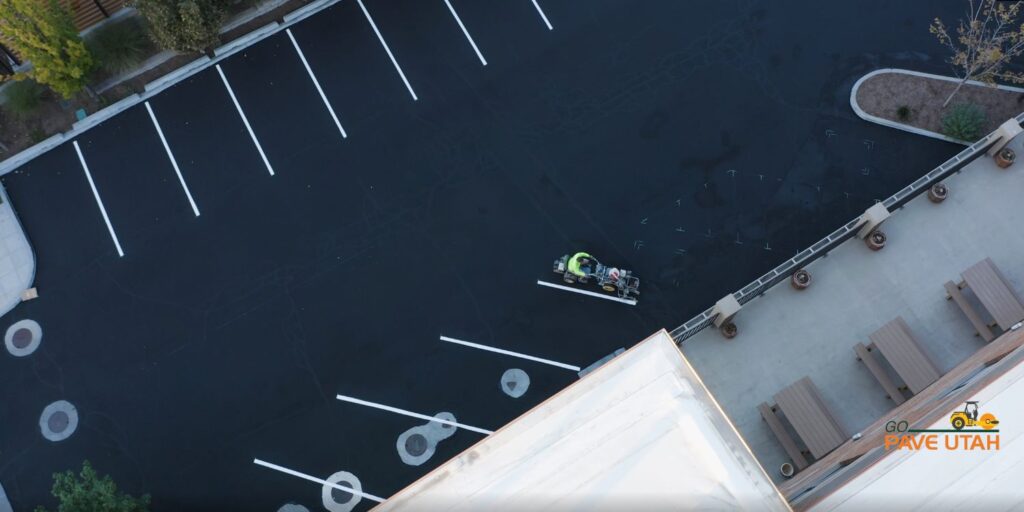

Applying a protective coating to the asphalt surface is essential for maintenance. This protective layer helps to preserve the natural oils in the asphalt, enhancing its resistance to water, oil, and other damaging substances. Asphalt seal coating is essential for safeguarding the asphalt from the damaging effects of the sun's ultraviolet rays, preventing fading and cracking. Applying striping and marking to the asphalt surface involves high quality paints designed to last through weathering conditions. These markings assist in directing drivers and pedestrians, while also enhancing the aesthetics of the parking lot. Maintenance work like seal coating and striping should be scheduled regularly, taking into account factors like traffic volume and weather conditions. Typically, seal coating should be done every 2-3 years, and striping should be done every year or two.

Common mistakes in maintaining asphalt driveways and parking lots include failing to perform regular sealcoating, delaying the repair of cracks and potholes, and improper drainage handling. Moreover, inadequate surface preparation can negatively affect the results of asphalt maintenance projects. To avoid these possible problems, it's important to take a proactive stance by performing regular inspections and quickly handling any maintenance needs. Being proactive and addressing maintenance needs promptly can help property owners avoid expensive repairs and premature deterioration of their asphalt surfaces.

Ensuring proper parking lot striping is essential for asphalt maintenance as it serves various important functions. First, it aids in creating clear and organized traffic patterns, facilitating safe and efficient navigation for drivers in the parking lot. In addition, well-marked parking lots delineate parking spaces, guaranteeing vehicles are parked in an organized fashion and optimizing the available space. Furthermore, striping enhances the safety of drivers and pedestrians by clearly marking designated areas and directing traffic. Additionally, properly maintained parking lot striping improves the overall look of the area, making it more inviting and visually attractive. Ensuring compliance with local regulations and accessibility standards is crucial, and well-marked parking lots are key to meeting these requirements.

Choosing the ideal product for pothole repair depends on various factors, like the size of the pothole and current weather conditions. Typically, hot mix asphalt is a popular choice for repairing larger potholes due to its durability and longevity. On the other hand, cold mix asphalt patches are suitable for smaller or temporary repairs. It's crucial to evaluate the specific characteristics of the pothole and seek expert advice or product recommendations to choose the best product for successful repair and upkeep.

Repairing potholes is a common practice to fix damaged areas on roads. This process involves filling the potholes with either hot mix asphalt or cold mix asphalt to restore the road surface and ensure smooth and safe driving conditions for vehicles.

Sealcoating is an essential investment for a variety of reasons. It acts as a protective barrier, defending the asphalt surface from the harmful effects of different elements. Thanks to this protective layer, the asphalt's durability is greatly increased, enabling it to resist damage from regular use. In addition to providing protection, sealcoating also helps improve the surface's appearance, giving it a rejuvenated and well-kept look. Choosing sealcoating as part of proactive maintenance can be a wise financial decision in the long term. Preventing potential damages can help you avoid costly repairs or the need for premature replacement, ultimately saving you both time and money. Hence, taking into account the numerous benefits it provides in terms of safeguarding, durability, appearance, and cost-effectiveness, sealcoating proves to be a valuable investment with substantial advantages.